Description

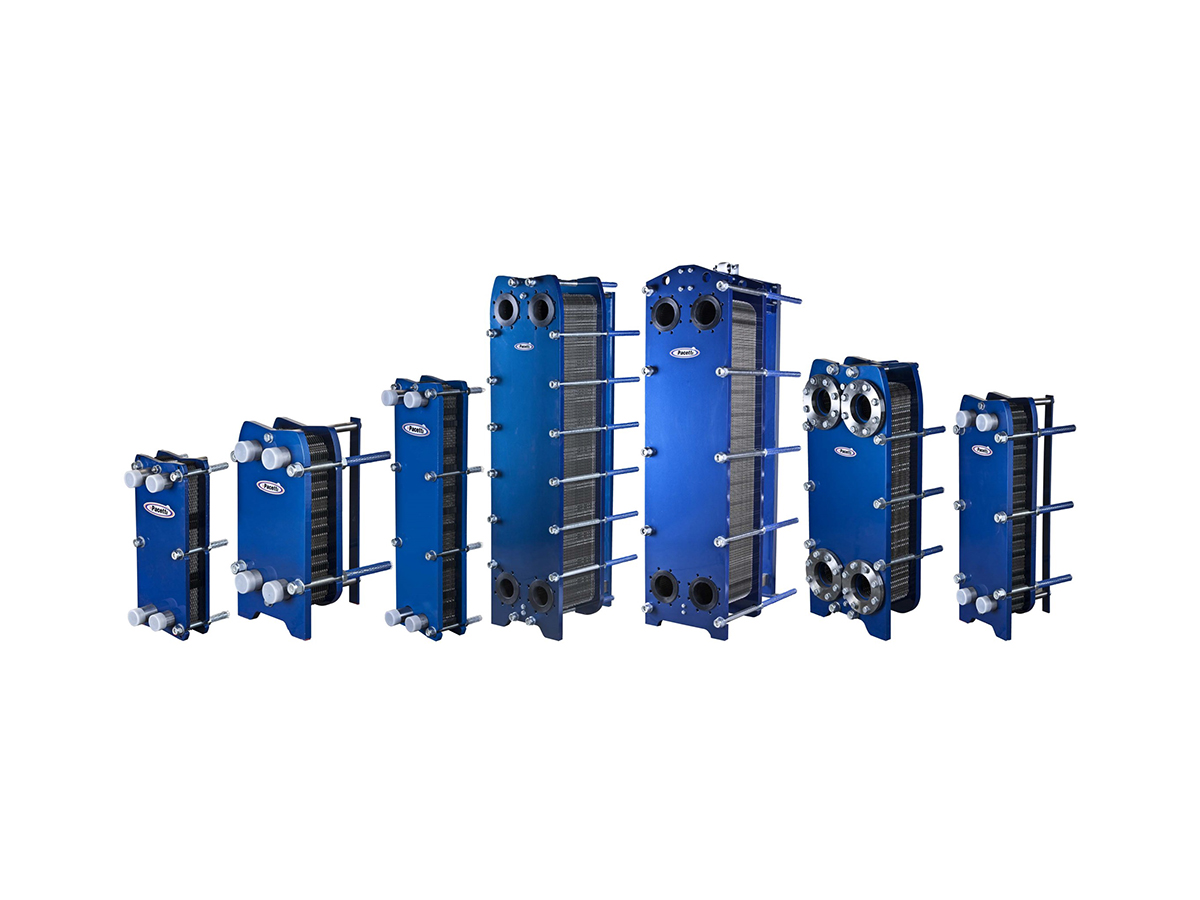

The range of gasketed plate heat exchangers PK has always been one of Pacetti's areas of excellence, where experience, build quality and the most comprehensive choice and adaptability to any system distinguish a top-quality product.Suitable for a wide variety of applications, these gasketed plate heat exchangers are the best solution for thermo-hydraulic and food systems and for industrial applications.

The extreme versatility of gasketed plate heat exchangers implies a variety of options to meet your needs; PK models are perfectly capable of responding to this requirement, offering:

- Plates with 2 different types of corrugation pattern, to prioritise heat exchange or reduce pressure drop. When properly mixed, they allow the heat exchanger to be perfectly designed in accordance with the required operating conditions;

- Plate construction material in 3 different types of Stainless Steel (AISI 304, AISI 316L, TITANIUM), to ensure compatibility with almost all fluids;

- Clip-on gaskets, which facilitate removal and replacement during maintenance;

- Gasket materials available in a choice of 3 different rubbers (EPDM, NBR, VITON), to ensure compatibility with a wide range of liquids and allow operating temperatures up to 180°C;

- Choice of different connection types other than the standard ones (threaded, Victaulic, flanged, etc.) and availability of EPDM rubber liners for exchangers with flanged connections (DN65, DN100, DN150) to prevent contact between circulating fluids and the carbon steel frame and ensure maximum hygiene.

Construction features

Accessories are available for each model, specially designed to fit the exchanger perfectly and achieve maximum performance.

The thermal insulation, covered externally with rigid aluminium sheet, can be completely and quickly removed using clips and fastening hooks and can also be removed after the pipes have been connected, to allow access to the exchanger during maintenance.

Internally, the insulation is made of closed-cell elastomeric foam (0.037 W/mK at 40°C) and is coupled with a semi-rigid aluminium foil.

When using PK exchangers for chilled water circuits, it is strongly recommended to use drip trays to be positioned below the exchanger itself. Made of Stainless Steel AISI 304, they are equipped with a ½" drain fitting for direct connection to the water drain of the system.

The floor mounting brackets make the installation more stable and, in the PK43 and PK80 models, also keep the entire exchanger raised to facilitate any maintenance operations.

All the different accessories can be used together, resulting in optimised space, cleanliness and pleasing aesthetics combined with complete technical functionality.